Eddy Current Full Body Testing System

Key Features

- Versions available for magnetic and non-magnetic materials.

- Suitable for high speed testing.

- Differential and absolute channels as standard.

- Full impedance plane analysis as standard.

- Defect marking system included as standard.

- Complete Data Logging of all Test Parameters easily stored, retrieved, hard-copied or downloaded.

- Instant recall of previously used setups.

Full body Eddy Current testing of tubular product is commonly an off-line (off the tube mill) process. It is very useful in cold draw operations to test the finished product before the ends are cropped. However, from time to time, the full body test is used as an on-line tool, mainly when small diameter (<25mm) tube is to be tested.

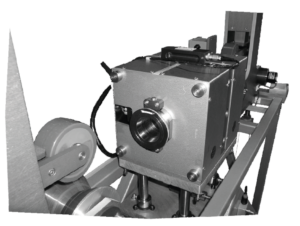

A full body eddy current test requires the tube to pass through an encircling coil. Size specific test coils are needed if several tube diameters are to be tested. If the test material is ferromagnetic a magnetic saturater is built into the test head with quick change pole pieces for the different product diameters.

A full body eddy current test requires the tube to pass through an encircling coil. Size specific test coils are needed if several tube diameters are to be tested. If the test material is ferromagnetic a magnetic saturater is built into the test head with quick change pole pieces for the different product diameters.

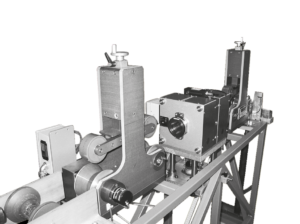

The off-line (off the tube mill), version of the full body eddy current unit is normally supplied as a complete test stand including pinch rolls and drive mechanism. This complete unit can be supplied by InspecTech to the correct run height for insertion into a conveyor line. The on-line (on the tube mill), version uses just the test head mounted on the mill bed, with the mill providing the required steady throughput of the tube. In the on-line arrangements, rotators or sliders can be provided to move the test head out of the run line for easier set-up and calibration.

When ferromagnetic material is saturated for eddy current testing, strong residual magnetic fields can exist in the product after testing. Consult InspecTech for demagnetizing options.